At Green Ship Technologies we specialize in Ship Design & Conversion services, catering to the evolving needs of the maritime industry. With a team of experienced naval architects, marine engineers, and project managers, we offer innovative solutions tailored to meet the unique requirements of our clients worldwide.

We take pride in our ability to utilize a range of specialized software applications tailored for marine engineering and design tasks. Our team has extensive experience in leveraging these tools to deliver innovative and reliable design solutions that meet the unique requirements of each vessel type.

Specializing in design conversion services, offering a comprehensive suite of solutions that enable our clients to transform their visions into reality. With a keen focus on meticulous planning, innovative solutions, and seamless execution, we are committed to delivering exceptional results that exceed expectations.

Offering a comprehensive range of solutions designed to enhance the design, structure, systems, and capabilities of vessels. With a focus on improving performance, efficiency, safety, and functionality, we provide expert guidance and seamless execution throughout the modification process.

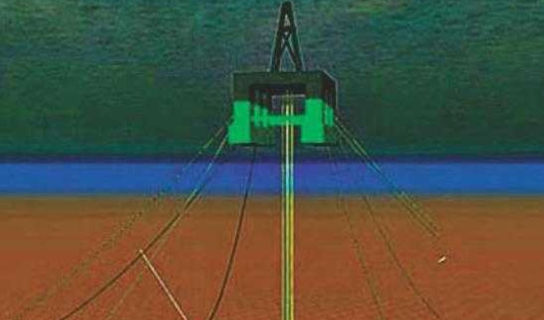

Well stimulation is a well intervention performed on an oil or gas well to increase production by improving the flow of hydrocarbons from the reservoir into the well bore. It may be done using a well stimulator structure or using off shore ships / drilling vessels, also known as “Well stimulation vessels”.

The vessel is designed to be capable of performing field support duties offering logistics capability comprising under deck liquid cargoes and deck cargo capabilities.

MWV are vessels designed as a platform for the loading and unloading of cargo or as a temporary workspace for the handling of equipment and materials.

Offshore construction vessels (OSV) are large and technologically advanced vessels used for deep sea and subsea constructions.

They typically equipped with lifting, positioning and pile-driving capabilities.

OSVs usually include Dynamic Positioning systems , cranes and ROVs (Remotely Operated Vehicles) that allow operations to be conducted in the harshest weather conditions.

Anchor Handling Tug Supply (AHTS) vessels are mainly built to handle anchors for oil rigs, tow them to location, and use them to secure the rigs in place.

Hybrid propulsion is any vehicle propulsion system that includes two or more sources of propulsion in one design, which can be used together or alternately.

A multi-purpose vessel (MPV) is a seagoing ship that is built for the carriage of a wide range of cargoes. Examples of these cargoes are: wood, steel, building materials, rolls of paper and bulk cargo.

Multi-purpose vessels can be divided into four categories: vessels with and without cargo gear, coastal trade liners and sea-river vessels. Bigger multi-purpose vessels are able to carry different kinds of loading on the same voyage. Smaller multi-purpose vessels do not have this advantage but they are employed to get into smaller harbours because of their limited draught.

A vessel designed to carry a relatively small number of passengers compared to larger cruise ships. These ships may vary in size and capacity but are generally smaller and more intimate, offering a more personalized experience for travelers. They might be used for various purposes, including short coastal cruises, river cruises, or ferry services between nearby destinations.

At Green Ship Technologies, a leading provider of specialized marine retrofit and conversion services. Our expertise lies in transforming existing vessels to adapt to new purposes, comply with regulatory requirements, and enhance performance and efficiency.

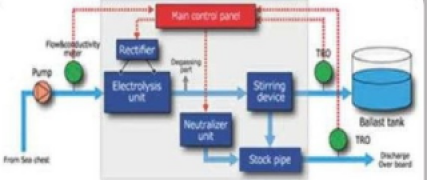

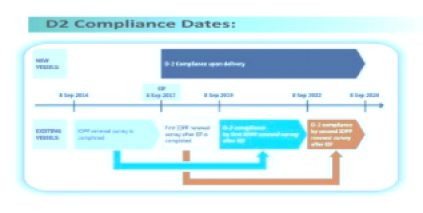

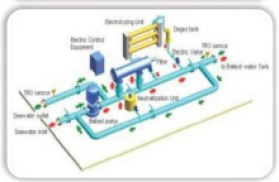

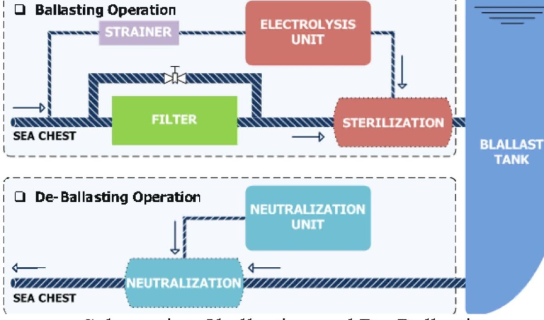

BWTS Installation Engineering refers to the integration of a BWTS in the vessel’s existing ballast water management infrastructure. at Green Ship Technologies we can perform the installation of BWTS on ships that were not originally equipped with the ballast water treatment system. This process is called ballast water treatment retrofit and is essential for compliance with the BWM Convention. The installation of the BWTS facilitates compliance with the D-2 standard, monitoring that the species in the discharged water are within the admissible limits.

Before proceeding with the installation of a BWTS, it’s crucial to inspect the vessel to determine its suitability and feasibility for the installation. This involves assessing the existing ballast water management infrastructure and identifying any necessary modifications or adjustments.

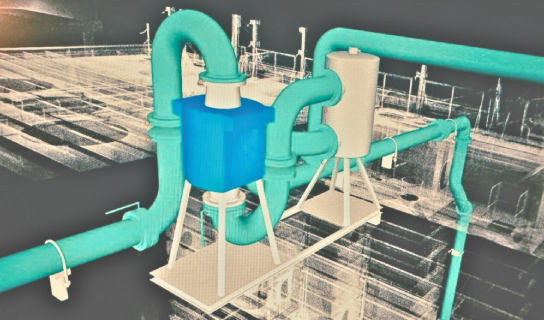

Utilizing advanced technology such as 3D laser scanning helps in capturing detailed and accurate measurements of the vessel’s spaces where the BWTS will be installed. This data is essential for the design and engineering phases.

Based on the information gathered from vessel inspections and 3D laser scanning, Green Ship Technologies creates detailed design and engineering drawings. These drawings are crucial for obtaining approval from classification societies (Class Approval) and ensuring client satisfaction (Client Approval).

Green Ship Technologies provides support and assistance during the installation phase, either at the shipyard during construction or in ports for retrofitting existing vessels. This involves coordinating with shipyard workers, overseeing the installation process, and ensuring compliance with relevant regulations and standards.

Our team comprises skilled Naval Architects, Marine Engineers, 3D Scanning Experts, Design Software Specialists, Piping, and Electrical Engineers. With their extensive experience, we can offer comprehensive design solutions and installation assistance.

Overall, these services offered by Green Ship Technologies play a vital role in facilitating the installation of BWTS on ships, ensuring compliance with the Ballast Water Management (BWM) Convention, and helping vessels meet the D-2 standard for ballast water treatment.

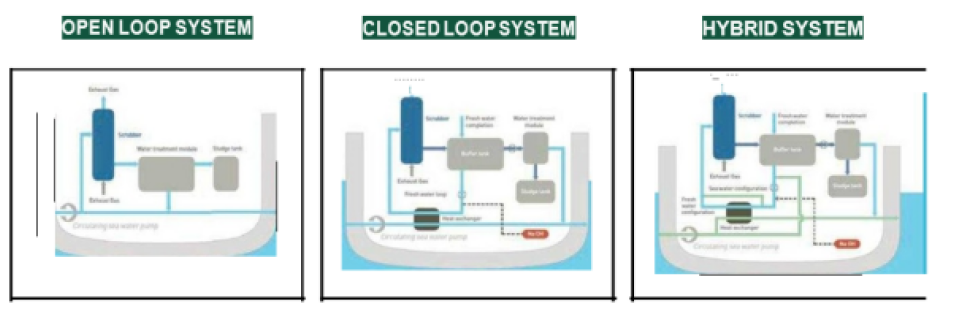

Scrubber Installation Engineering, a ship scrubber, also known as an exhaust gas cleaning system (EGCS), is an emissions control device that removes pollutants from the exhaust gas and reduces the amount emitted by ships, making them a more environmentally-friendly mode of transportation.

We boast an exceptional team comprising naval architects, marine engineers, 30 scanning experts, design software specialists, as well as piping and electrical engineers. With extensive experience, our team is adept at delivering comprehensive design solutions and providing installation assistance for various projects.

In addition, we also represent renowned manufacturers of SOx scrubbers, providing high-quality solutions to meet emissions regulations and enhance environmental sustainability in maritime operations.

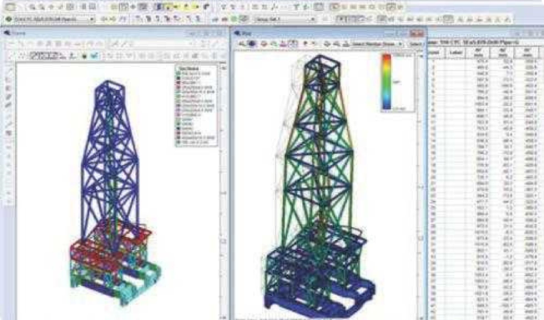

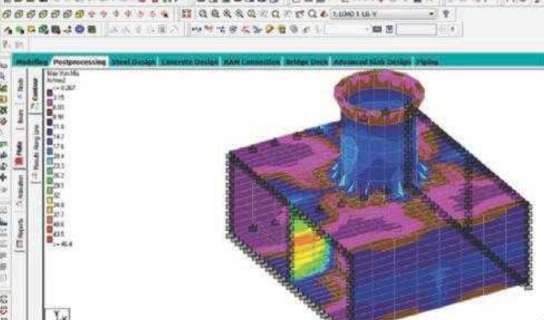

At Green Ship Technologies, we specialize in offshore engineering solutions tailored to meet the diverse needs of projects located in offshore environments.

Offshore engineering encompasses a wide range of services aimed at designing, constructing, and maintaining structures and facilities in challenging marine environments, including oil and gas platforms, wind farms, and marine infrastructure.

With our expertise in offshore engineering, we offer comprehensive services that cover various aspects of project development, from concept design to execution and operation.